Guangxi Automobile Group: The "Smart" Manufacturing Breakthrough Path of a Century-Old Enterprise

Date: 2025-07-18 Categories: News Hits: 371

As Guangxi's first century-old industrial enterprise, Guangxi Automobile Group has witnessed and participated in the development of China's automotive industry. Today, riding the wave of artificial intelligence, the company has embarked on a unique "smart" manufacturing path, using a full-chain intelligent transformation as its breakthrough. This provides valuable insights for the regional automotive industry's upgrade.

Full-chain Acceleration: Smart Genes Permeate the Entire Production Process

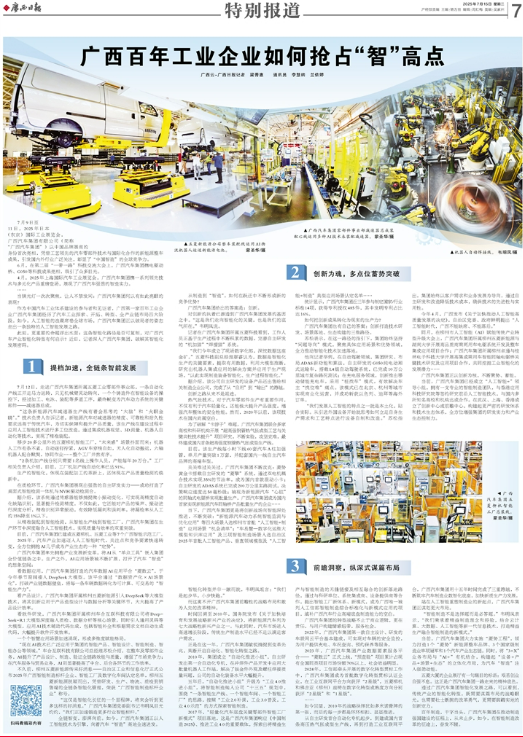

Inside the automated production line of Wuling Industrial's Components Division, robotic arms operate with precision. Intelligent equipment systematically completes the processing, electrophoresis, and assembly of castings, ultimately producing new energy vehicle (NEV) reducer assemblies. This line integrates AI technologies like machine vision and 3D measurement, functioning like a "smart brain." It meets the stringent requirements for high precision and high reliability of NEV components.

20 kilometers away, the Wuling Liuji Smart Factory exudes an even more "futuristic" atmosphere: AGVs handle automated material handling, six-axis robots work in coordination. Just one operator manages two machining lines, achieving an annual capacity of 200,000 units with an automation rate of 91%. In quality inspection, the self-developed desktop smart inspection system and NVH vibration test bench capture minute vibrations via sensors, reducing the defect escape rate from 15% (manual inspection) to below 1%, boosting both accuracy and efficiency.

To date, Guangxi Automobile Group has established seven Guangxi Smart Model Factories, including Wuling Industrial and Wuling Liuji. Moreover, AI technology is extending beyond production into the entire value chain: The automotive data AI platform "LingShuYun," integrated with large models, enables the assetization and scenario-based application of vehicle data, transforming data into "intelligent productivity." Liuzhou Wuling New Energy utilizes large models for product styling design, while Liuzhou Chehe Interconnect employs AI-assisted code generation, significantly improving software development efficiency.

Thanks to its full-chain intelligent management, Liuzhou Wuling New Energy was named a "2025 Guangxi Intelligent Manufacturing Benchmark Enterprise," showcasing the company's exemplary strength in intelligent transformation.

Innovation as the Soul: Multi-point Breakthroughs Fortify the Technological Moat

Innovation is the core driving force behind Guangxi Automobile Group's intelligent transformation. At Wuling Technology, self-developed systems like "Machining Cat" and "Welding Cat" provide solutions for robot integration by deeply analyzing production data, enabling intelligent upgrades in manufacturing equipment and processes. These technologies have evolved from "in-house use" to "external output," empowering the broader industry.

In tackling core technological challenges, the company collaborated with universities and research institutes to overcome bottlenecks. Post-2020, it built China's first ultra-high-strength steel tube hot gas bulge forming production line, capable of producing 60 sets of car A-pillar reinforcement tubes per hour, with a monthly output exceeding 10,000 sets. This contributes to vehicle lightweighting and enhanced safety. Furthermore, the self-developed "Lingqing" hybrid system achieves a 35% fuel saving rate. The G050 pure-electric van featuring L4 autonomous driving completed 100,000 kilometers of urban road condition testing. The coaxial electric drive axle has entered mass production, solidifying the company's position as a leader in core NEV technologies in China.

Over the past three years, Guangxi Automobile Group has participated in formulating 14 national/industry standards and secured 485 patent authorizations (16% being invention patents). Through the three-dimensional path of "technology R&D – scenario implementation – ecosystem building," the company promotes the efficient conversion of smart technologies: Mobile energy storage charging vehicles solve the "difficulty finding charging points," operating commercially in multiple regions and entering overseas markets; Collaborations with Hunan University, Guilin University of Electronic Technology, and others deepen the potential of "AI + Manufacturing."

Currently, the company has established an "AI+" leadership group and a dedicated smart manufacturing team. It has set up innovation centers in Wuhan, Shanghai, and Hong Kong, partnering with institutions like the Hong Kong Applied Science and Technology Research Institute (ASTRI) to develop cutting-edge technologies, building a multi-tiered R&D and ecosystem.

Forward-looking Strategy: Deepening the Intelligent Future

Guangxi Automobile Group's intelligent transformation began with a strategic decision in 2010. That year, it formed an "Automation Promotion Team" and developed its first automated special-purpose machine. In 2015, this was upgraded to an "Industry 4.0 Promotion Team," formally incorporating smart manufacturing into its plans. In 2017, the "New Model Project for Smart Factory of Lightweight Automotive Chassis Key Components" was implemented, becoming Guangxi's first Ministry of Industry and Information Technology (MIIT) Smart Manufacturing Comprehensive Standardization and New Model Application project... Over 15 years, the company completed a triple leap from automation to an industrial internet platform.

In 2024, the company became one of the first batch of enterprises certified for digital transformation standardization. Subsidiaries like Wuling Liuji received digital transformation maturity ratings. Today, the company is implementing the "LingShi Project," focusing on one "LingShi" NEV brand, three national-level manufacturing champion products, and one automotive industry ecosystem chain. It promotes the deep integration of its "3+X" business with "AI+," creating a multi-dimensional layout of "Equipment + Products + Scenarios + Ecosystem."

"Smart manufacturing is a compulsory question," said Wei Mingfeng, Deputy Party Secretary of the Group. "The company will carry forward the spirit of 'hard work and self-reliance,' integrating lean manufacturing with new-generation information technologies. Amidst the wave of AI reshaping manufacturing, we will continue writing new 'smart' chapters for our century-old enterprise."

G200 Hybrid MPV – Versatile & ...

G200 Hybrid MPV – Versatile & ...  G050 - The Best Choice for Urb...

G050 - The Best Choice for Urb...  Wuling Golden Card - Luxury, S...

Wuling Golden Card - Luxury, S...  Ruichi EC75 – Modern 2-Seater ...

Ruichi EC75 – Modern 2-Seater ...  Saic Motor Wuling Yangguang – ...

Saic Motor Wuling Yangguang – ...  Saic Datong person with power ...

Saic Datong person with power ...  Brilliance Xinyuan E3L – Advan...

Brilliance Xinyuan E3L – Advan...  Jinhu EV48 – Efficient Electri...

Jinhu EV48 – Efficient Electri...  V5 – High-Performance 2-7 Seat...

V5 – High-Performance 2-7 Seat...  King Long European Version Lig...

King Long European Version Lig...  FM Oley – Robust Commercial Va...

FM Oley – Robust Commercial Va...  Dongfeng Capstar – Versatile 3...

Dongfeng Capstar – Versatile 3...  FOTON LINGHANG M5 – Spacious S...

FOTON LINGHANG M5 – Spacious S...  Geely Farizon H8E - The Ultima...

Geely Farizon H8E - The Ultima...  Dongfeng EV350 - Leading the W...

Dongfeng EV350 - Leading the W...  BYD T5 - Revolutionize Your Co...

BYD T5 - Revolutionize Your Co...  Geely Farizon F1e - The Ideal ...

Geely Farizon F1e - The Ideal ...  Dongfeng EV150 - Your Ideal El...

Dongfeng EV150 - Your Ideal El...  UFO Aochi - Unveiling the Myst...

UFO Aochi - Unveiling the Myst...  DFAC Captain - Unleashing the ...

DFAC Captain - Unleashing the ...  SRM-T52 - Versatile and Effici...

SRM-T52 - Versatile and Effici...  SRM-T50 Electric Vehicle - You...

SRM-T50 Electric Vehicle - You...  SRM-S22 - Advanced and Reliabl...

SRM-S22 - Advanced and Reliabl...  SAIC Maxus Interstellar L – 5-...

SAIC Maxus Interstellar L – 5-...  Great Wall Fengjun 5 – Reliabl...

Great Wall Fengjun 5 – Reliabl...  Zhengzhou Nissan Ruiqi 7 – Pow...

Zhengzhou Nissan Ruiqi 7 – Pow...  Chongqing Changan Lantuo Zhe –...

Chongqing Changan Lantuo Zhe –...  JAC T8PRO Rui Xing Edition – 5...

JAC T8PRO Rui Xing Edition – 5...  CNG S6 - 2.0L: The High - Perf...

CNG S6 - 2.0L: The High - Perf...  CNG Ruihang M60: Your Green an...

CNG Ruihang M60: Your Green an...  CNG Ruihang M80: The Ideal CNG...

CNG Ruihang M80: The Ideal CNG...  CNG S6 - 1.6L: Your Economical...

CNG S6 - 1.6L: Your Economical...  CNG Wuling - Xinka: The Effici...

CNG Wuling - Xinka: The Effici...  SY335BH 33T Excavator | SANY H...

SY335BH 33T Excavator | SANY H...  Qingdao Jiefang HanV 320HP 8X4...

Qingdao Jiefang HanV 320HP 8X4...  SAC9000C8-8 All-Terrain Crane ...

SAC9000C8-8 All-Terrain Crane ...  18T Pure Electric Compression ...

18T Pure Electric Compression ...  TEG5180GSSADFBEV1 Electric Wat...

TEG5180GSSADFBEV1 Electric Wat...  XCMG XGH5180TXCLBEV Pure Elect...

XCMG XGH5180TXCLBEV Pure Elect...  ZLF5290GXFPM120 Foam/Water Tan...

ZLF5290GXFPM120 Foam/Water Tan...  Tenglong Ambulance SYC5040 XJH...

Tenglong Ambulance SYC5040 XJH...  Chengli Jiefang J6 8x4 Aluminu...

Chengli Jiefang J6 8x4 Aluminu...  Feidian W5 163HP 4X2 Refrigera...

Feidian W5 163HP 4X2 Refrigera...  Zongshen ZS500ZH-9 3-Wheeled M...

Zongshen ZS500ZH-9 3-Wheeled M...  Zongshen ZS500ZH-3S 3-Wheeled ...

Zongshen ZS500ZH-3S 3-Wheeled ...