Wuling New Energy Conducts High-Temperature Calibration Tests in Turpan, Xinjiang

Date: 2025-07-24 Categories: News Hits: 360

In July, Wuling New Energy's summer calibration team conducted high-temperature calibration tests for vehicles in Turpan, Xinjiang. In Turpan, the average maximum temperature from June to August exceeds 40℃, with the highest surface temperature reaching 80℃. During the test, the surface temperature exceeded 70℃ and the perceived temperature reached 52℃.

The tests involved joint calibration of the vehicle's Battery Management System (BMS), Vehicle Control Unit/Hybrid Electronic Control Unit (VCU/HECU), Thermal Management Control Unit (TMCU), etc., to verify the vehicle's power, heat dissipation, reliability and durability under high-temperature conditions. For extended-range vehicles, key tests were carried out to ensure that when the battery output is insufficient at high temperatures, the range extender operates without detonation and achieves balanced energy distribution, thus guaranteeing normal vehicle operation. The collected data will support subsequent product iterations and upgrades.

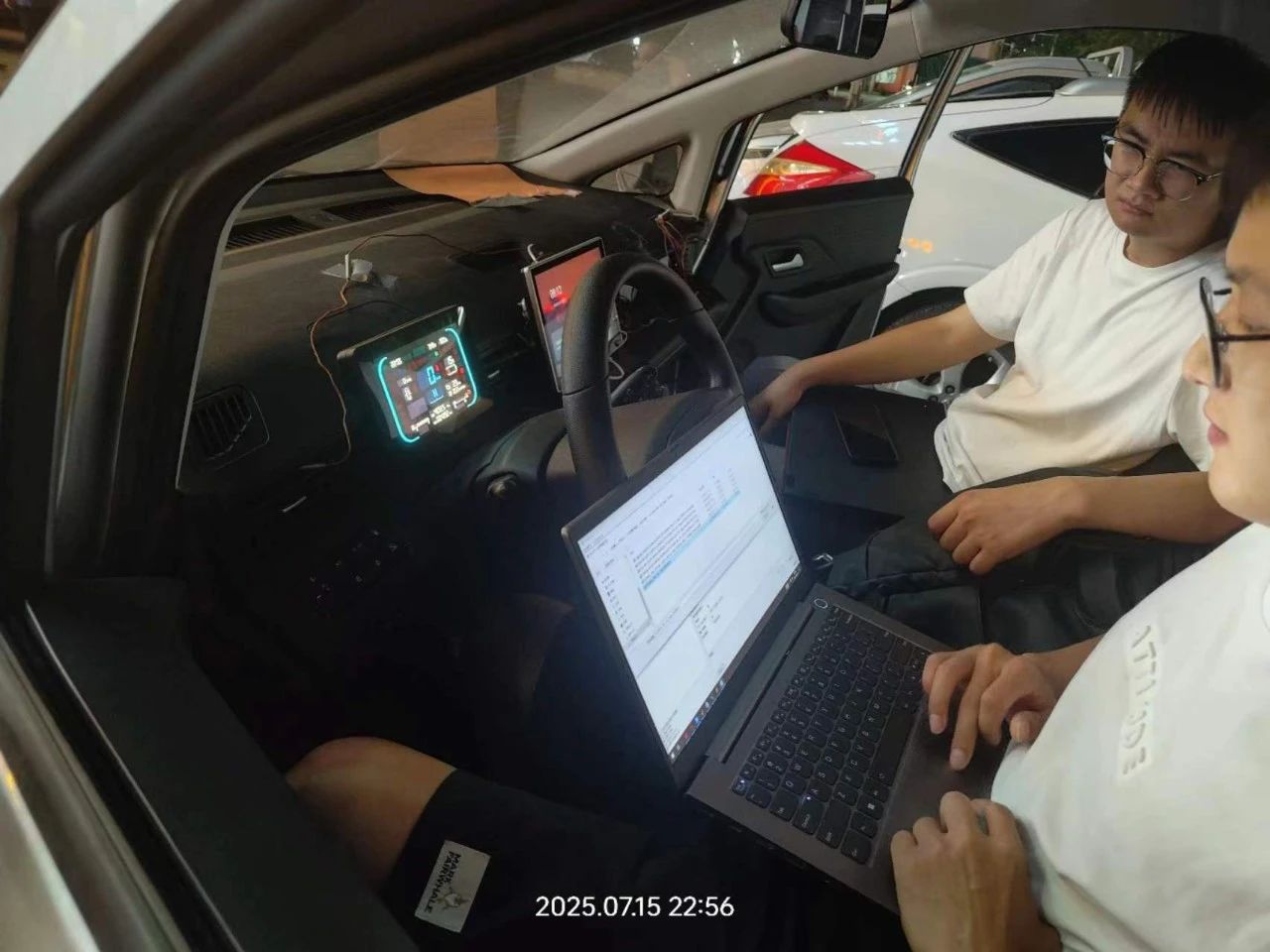

The daily workflow of the test team is as follows: Before departure in the early morning, they conduct safety briefings, review data from the previous day, and clarify the day's test priorities; from 2 pm to 5 pm (a key test period when the surface temperature exceeds 70℃), engineers perform tasks such as under-vehicle inspections and recording air-conditioning outlet temperatures under a perceived temperature of around 45℃; at 10 pm, the team holds experience exchanges and problem discussions, and adjusts calibration parameters overnight.

This high-temperature calibration is part of the implementation of the Lingshi Project "131" strategy. The three extreme condition calibrations are still ongoing – stay tuned.

G200 Hybrid MPV – Versatile & ...

G200 Hybrid MPV – Versatile & ...  G050 - The Best Choice for Urb...

G050 - The Best Choice for Urb...  Wuling Golden Card - Luxury, S...

Wuling Golden Card - Luxury, S...  Ruichi EC75 – Modern 2-Seater ...

Ruichi EC75 – Modern 2-Seater ...  Saic Motor Wuling Yangguang – ...

Saic Motor Wuling Yangguang – ...  Saic Datong person with power ...

Saic Datong person with power ...  Brilliance Xinyuan E3L – Advan...

Brilliance Xinyuan E3L – Advan...  Jinhu EV48 – Efficient Electri...

Jinhu EV48 – Efficient Electri...  V5 – High-Performance 2-7 Seat...

V5 – High-Performance 2-7 Seat...  King Long European Version Lig...

King Long European Version Lig...  FM Oley – Robust Commercial Va...

FM Oley – Robust Commercial Va...  Dongfeng Capstar – Versatile 3...

Dongfeng Capstar – Versatile 3...  FOTON LINGHANG M5 – Spacious S...

FOTON LINGHANG M5 – Spacious S...  Geely Farizon H8E - The Ultima...

Geely Farizon H8E - The Ultima...  Dongfeng EV350 - Leading the W...

Dongfeng EV350 - Leading the W...  BYD T5 - Revolutionize Your Co...

BYD T5 - Revolutionize Your Co...  Geely Farizon F1e - The Ideal ...

Geely Farizon F1e - The Ideal ...  Dongfeng EV150 - Your Ideal El...

Dongfeng EV150 - Your Ideal El...  UFO Aochi - Unveiling the Myst...

UFO Aochi - Unveiling the Myst...  DFAC Captain - Unleashing the ...

DFAC Captain - Unleashing the ...  SRM-T52 - Versatile and Effici...

SRM-T52 - Versatile and Effici...  SRM-T50 Electric Vehicle - You...

SRM-T50 Electric Vehicle - You...  SRM-S22 - Advanced and Reliabl...

SRM-S22 - Advanced and Reliabl...  SAIC Maxus Interstellar L – 5-...

SAIC Maxus Interstellar L – 5-...  Great Wall Fengjun 5 – Reliabl...

Great Wall Fengjun 5 – Reliabl...  Zhengzhou Nissan Ruiqi 7 – Pow...

Zhengzhou Nissan Ruiqi 7 – Pow...  Chongqing Changan Lantuo Zhe –...

Chongqing Changan Lantuo Zhe –...  JAC T8PRO Rui Xing Edition – 5...

JAC T8PRO Rui Xing Edition – 5...  CNG S6 - 2.0L: The High - Perf...

CNG S6 - 2.0L: The High - Perf...  CNG Ruihang M60: Your Green an...

CNG Ruihang M60: Your Green an...  CNG Ruihang M80: The Ideal CNG...

CNG Ruihang M80: The Ideal CNG...  CNG S6 - 1.6L: Your Economical...

CNG S6 - 1.6L: Your Economical...  CNG Wuling - Xinka: The Effici...

CNG Wuling - Xinka: The Effici...  SY335BH 33T Excavator | SANY H...

SY335BH 33T Excavator | SANY H...  Qingdao Jiefang HanV 320HP 8X4...

Qingdao Jiefang HanV 320HP 8X4...  SAC9000C8-8 All-Terrain Crane ...

SAC9000C8-8 All-Terrain Crane ...  18T Pure Electric Compression ...

18T Pure Electric Compression ...  TEG5180GSSADFBEV1 Electric Wat...

TEG5180GSSADFBEV1 Electric Wat...  XCMG XGH5180TXCLBEV Pure Elect...

XCMG XGH5180TXCLBEV Pure Elect...  ZLF5290GXFPM120 Foam/Water Tan...

ZLF5290GXFPM120 Foam/Water Tan...  Tenglong Ambulance SYC5040 XJH...

Tenglong Ambulance SYC5040 XJH...  Chengli Jiefang J6 8x4 Aluminu...

Chengli Jiefang J6 8x4 Aluminu...  Feidian W5 163HP 4X2 Refrigera...

Feidian W5 163HP 4X2 Refrigera...  Zongshen ZS500ZH-9 3-Wheeled M...

Zongshen ZS500ZH-9 3-Wheeled M...  Zongshen ZS500ZH-3S 3-Wheeled ...

Zongshen ZS500ZH-3S 3-Wheeled ...